Rubber bridge support features

The rubber bridge support is a special rubber shock absorber that is usually installed between the superstructure (bridge) of the railway or highway bridge and the pier. Its role is to effectively transfer the total load (including static load and live load) that the bridge body bears to the pier. It can also adapt to the needs of deformation of the superstructure, so that its actual bearing capacity is consistent with the mechanical calculation. It can be said that the bridge support integrates both the superstructure and the bridge abutment with minimal force, thereby transferring the movement caused by temperature changes, concrete shrinkage and load to the pier. With the rapid development of national railways and highway facilities, the application of rubber bridge supports with them has also grown rapidly, becoming a rubber shock absorber with a large amount of surface.

Rubber bridge bearings are mainly divided into two types: plate type and basin type.

(1) Slab bridge support

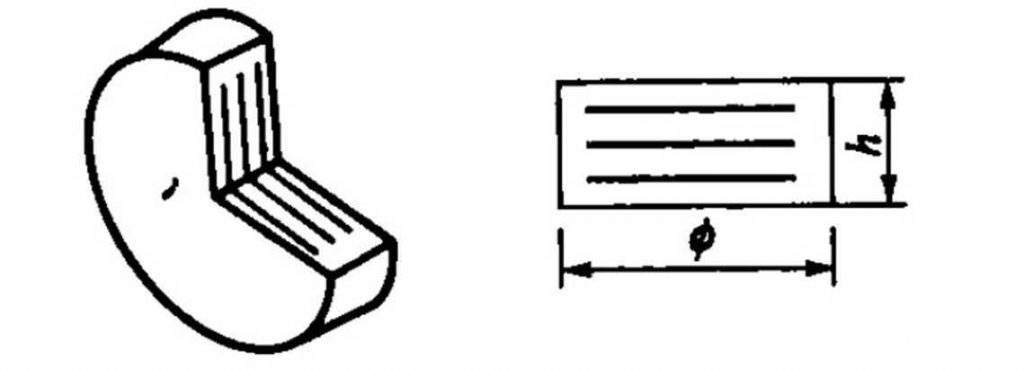

The slab bridge bearing is named for its shape. It is usually made up of alternating layers of film and reinforced steel plates. The number of steel plates varies from 2 to 6 layers. The top and bottom layers are both film layers. The steel plate acts as a reinforcement to prevent lateral expansion of the rubber, thereby increasing the overall compressive strength of the support, but the steel plate is not allowed to be exposed. These supports rely on their own shear deformation to accommodate the horizontal deformation (elongation or shortening) of the bridge. Usually the plate supports are suitable for medium and small span bridges.

According to the shape, the plate supports are divided into rectangular and circular, which are specially designed for cylindrical piers. The circular plate support also has the following features:

Round plate rubber bridge bearing

1 The deformation adaptability is strong, and it is not limited by the direction, and can absorb deformation from all directions of the upper structure of the bridge;

2 There is no local stress concentration problem, which is common in rectangular plate bearings;

3 There are no directional problems during installation.