PTFE panel rubber bearing and basin bearing

Polytetrafluoroethylene (PTFE) panel rubber bearing

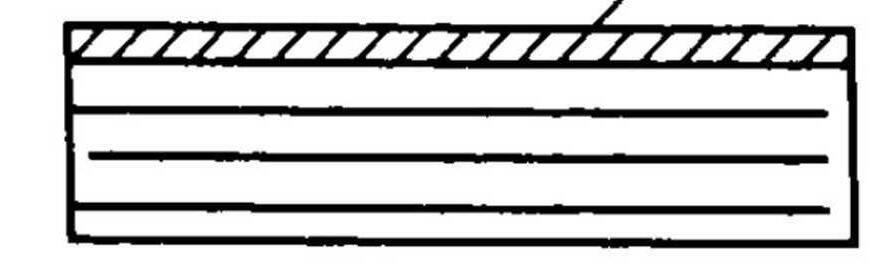

The rubber bearing is constructed in the same manner as the above-mentioned plate support, except that a layer of PTFE (thickness 1.5 to 3 mm) is applied to the top surface. The shape can also be rectangular or circular. The friction coefficient between it and the stainless steel plate is small, and it can adapt to the large horizontal displacement of the long-span bridge, thereby playing the role of “active support”. The mechanical properties of this type of support are the same as those of ordinary plate rubber bearings, but it is required to pre-bury the stainless steel plate at the corresponding position of the beam bottom (with the support of the Teflon panel) to minimize the friction between the two. Activity adaptability is optimal.

PTFE panel rubber bearing

Basin rubber bearing

The basin support structure is more complex than the plate support, from the upper support plate, seal ring, PTFE

The panel, the rubber block and the lower support are composed of a diameter to a thickness ratio of usually 15∕1. Its load carrying capacity and displacement are larger than the plate support, because the support body is sealed inside the steel basin. In this way, the deformation is constrained, so that the compressive strength and the bearing capacity can be greatly improved; and the ultra-low friction coefficient of the PTFE panel and the stainless steel plate at the bottom of the beam body is utilized, so that the displacement amount significantly exceeds the support of the ordinary structure, so as to be smoothly realized. Displacement in the horizontal direction.